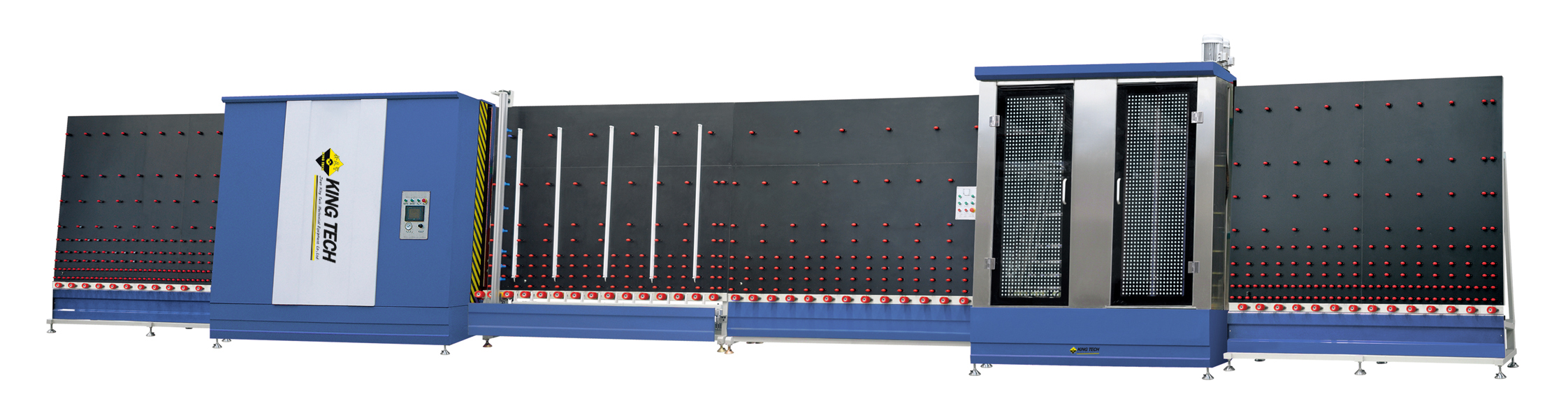

Linha de produção automática de vidro isolante

- KING TECH

- CHINA

- 15-25 DIAS

- 50 CONJUNTOS / MÊS

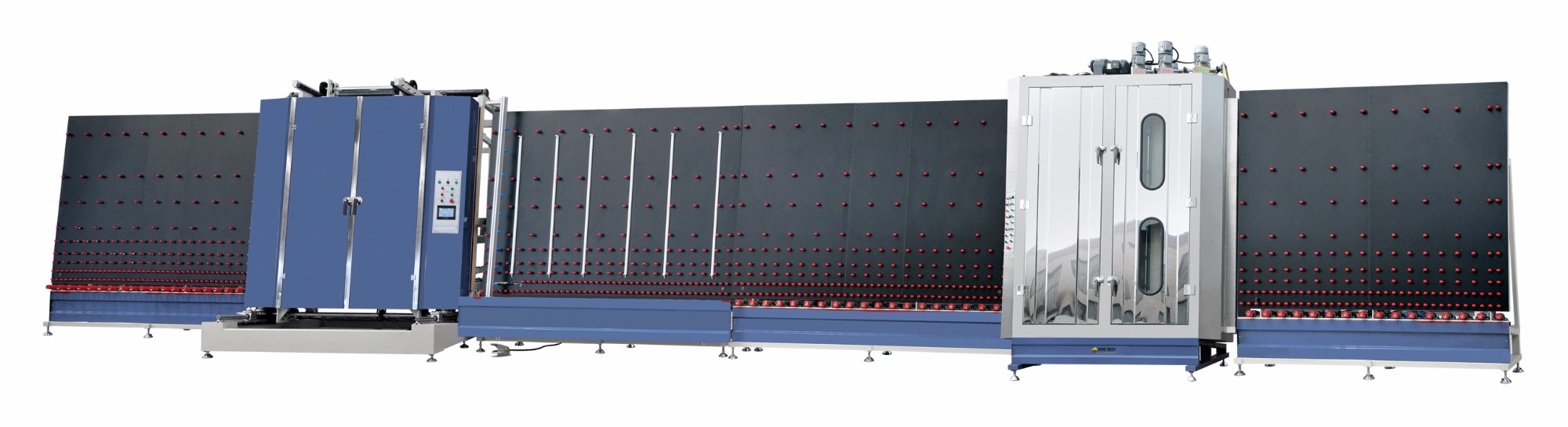

A linha de produção de vidro isolante totalmente automática adota a mais avançada tecnologia de fabricação IG e artesanato do mundo. Possui todas as funções de montagem do painel interno e processo de vidro escalonado.

A linha pode processar unidade dupla, unidade tripla e unidade de passo com alta eficiência. A prensa de enchimento automática de gás opcional para montagem mantém a perda de gás e os tempos de ciclo baixos. No final da linha, a estação de vedação garante estabilidade e, acima de tudo, cantos perfeitos.

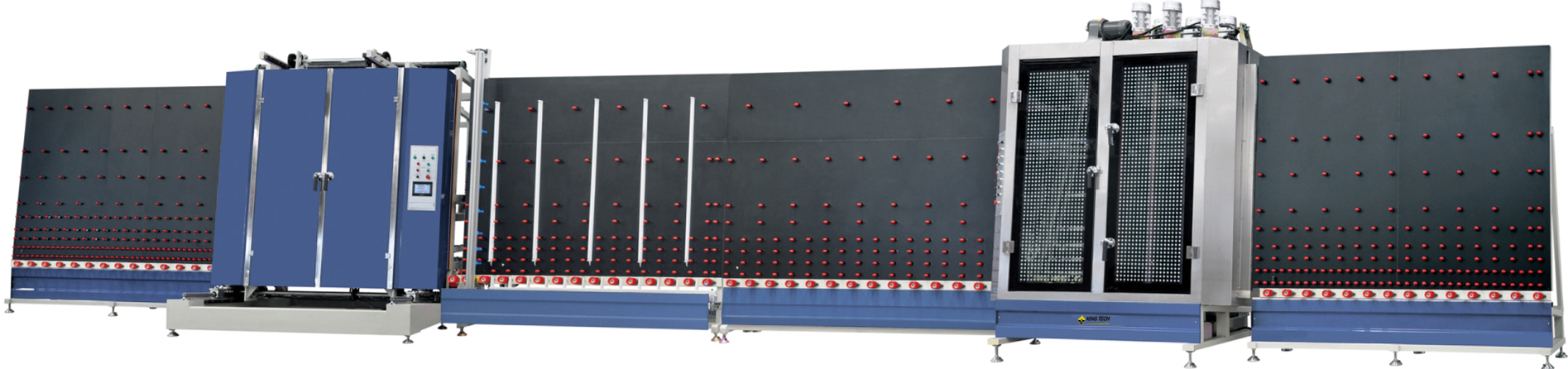

Linha de produção de vidro isolante automático da série KT-IGL

Introdução

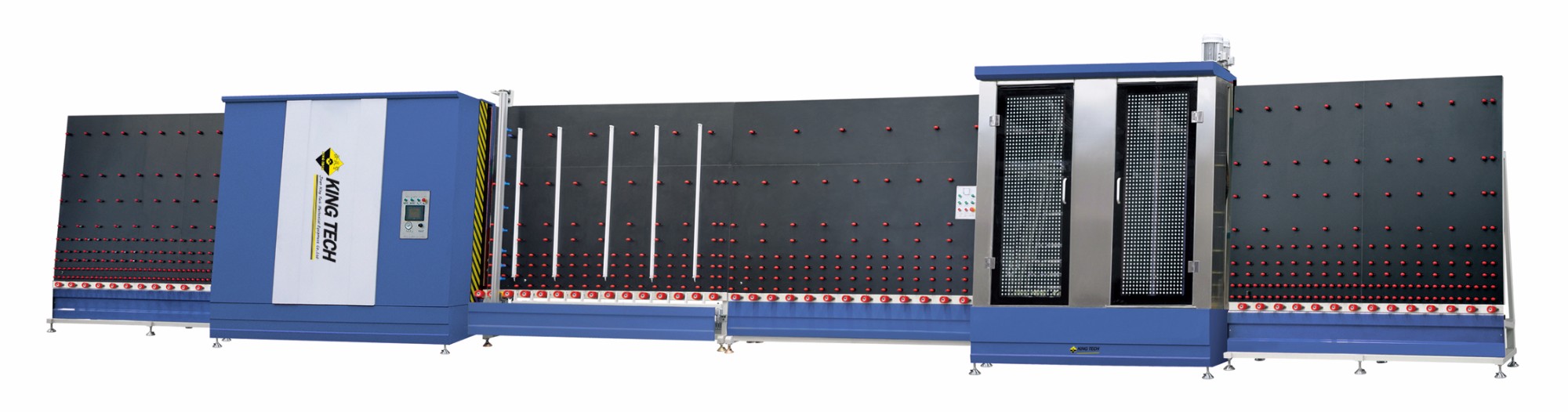

Linha IG COM Robô de Vedação

Características

A linha IG com o robô de vedação é adequada principalmente para o uso de fábrica de produção de alto padrão da unidade IG. Com alto desempenho de trabalho e produção em massa.

Esta linha de produção adota a mais avançada tecnologia de fabricação IG e artesanato do mundo. Possui todas as funções de montagem do painel interno e processo de vidro escalonado. Esta linha de produção pode processar unidade dupla, unidade tripla e unidade de passo com alta eficiência. No final da linha, a estação de vedação garante estabilidade e, acima de tudo, cantos perfeitos.

A linha Full IG atende a diversos requisitos, tanto de alta velocidade quanto de produção intensiva em massa. Está especialmente equipado para a produção de elementos de vidro isolante revestido com espaçadores de alumínio. A prensa de montagem e enchimento de gás mantém a perda de gás e os tempos de ciclo baixos. No final da linha, a estação de vedação garante estabilidade e, acima de tudo, cantos perfeitos.

Linha de produção automática de vidro isolante KT-IGL1600 / 1800 (sem robô de vedação)

Seção de recursos da máquina de prensagem:

Itália Nível técnico de produção, instalação e mecânica.

Transdutor japonês da Panasonic, monitor Taiwan Wenview, sensor coreano Autonics para manter as principais peças elétricas funcionando mais de 50.000.000 de vezes. Todo o transporte rodando em vidro automático, acelera duas ou três peças de vidro ou em diferentes tamanhos de vidro. Ajusta o tamanho de diferentes vidros pelos motores para obter um funcionamento automático mais alto e mais exato.

Projeto mais prático e conveniente de pressionar parte sobre vácuo, condução pneumática. Pode lidar com dois ou três pedaços de vidro e paredes cortinas.

Existe um sistema mecânico de dispositivos de posição e adsorção de Taiwan para pressionar a posição correta para evitar deslocamento.

Processo de prensagem de vidro oco razoável para manter todo o rolo com uma vida muito mais longa e também para evitar a quebra de qualquer vidro.

A estrutura é soldada por tubo retangular internacional de 2,75 mm com estrutura de alta resistência.

Seção deMáquina de lavar e secar roupaCaracterísticas:

Soldagem em aço inoxidável com estrutura de alta resistência; Teto superior em chapa de aço inoxidável espessado de 12 mm, fundo em aço inoxidável de 5 mm de espessura e lateral em aço inoxidável de 2 mm de espessura.

Existem quatro escovas resistentes a altas temperaturas com sistema de lavagem por spray para manter todo o processo limpo mais fácil, rápido, completo e abrangente.

Todas as peças de reposição na caixa de lavagem são feitas de material inoxidável ou impermeável para manter toda a seção longa e estável.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Technical Parameters:

Model | KT-IGL1600 | KT-IGL1800 |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480V 50/60 Hz |

Total Power | 13.5 KW | 15.5 KW |

Max Glass Size | 1600×2500 mm(custom) | 1800*2500 mm |

Min Glass Size | 300*400 mm | 300*400 mm |

Glass Thickness | 4-12 mm | 4-12 mm |

Working Speed | 4-48 m/min | 6-48 m/min |

Total Weight | 3300 kg | 3800 kg |

Size of Line(L×W×H) | 13500*2350*2450 mm | 15500*2350*2650 mm |

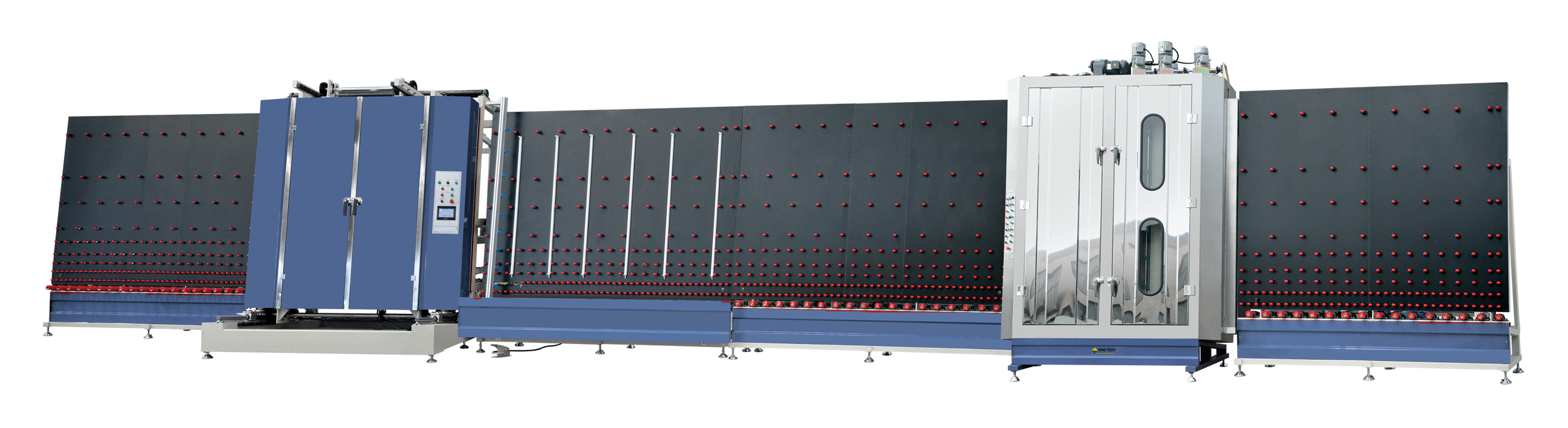

KT-IGL2000/2200 Full Automatic Insulating Glass Production Line(without sealing robot)

Section of Pressing Machine Features:

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position +mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine Features:

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are four High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Germany Imported Brush, got High temperature, anti-static function.

Technical Parameters:

Model | KT-IGL2000 | KT-IGL2200 |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480 V 50/60 Hz |

Total Power | 19.5 KW | 23.5 KW |

Max Glass Size | 2000×2500 mm | 2200×3000 mm |

Min Glass Size | 300×450 mm | 300×450 mm |

Glass Thickness | 4-18 mm | 4-18 mm |

Working Speed | 8-48 m/min | 8-48 m/min |

Total Weight | 4500 kg | 4900 kg |

Size of Line(L×W×H) | 17000*2660*3030 mm | 18500*2660*3530 mm |

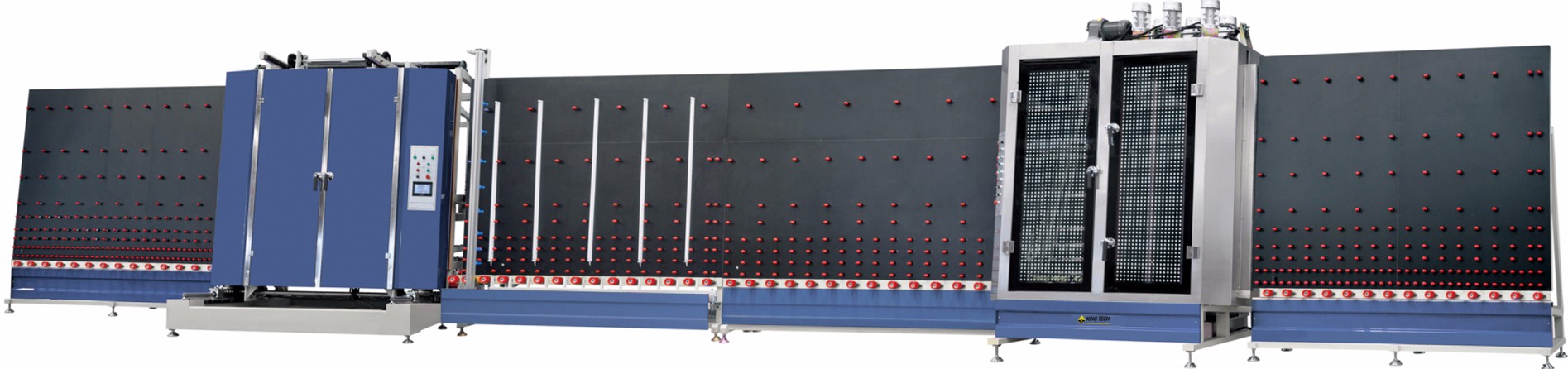

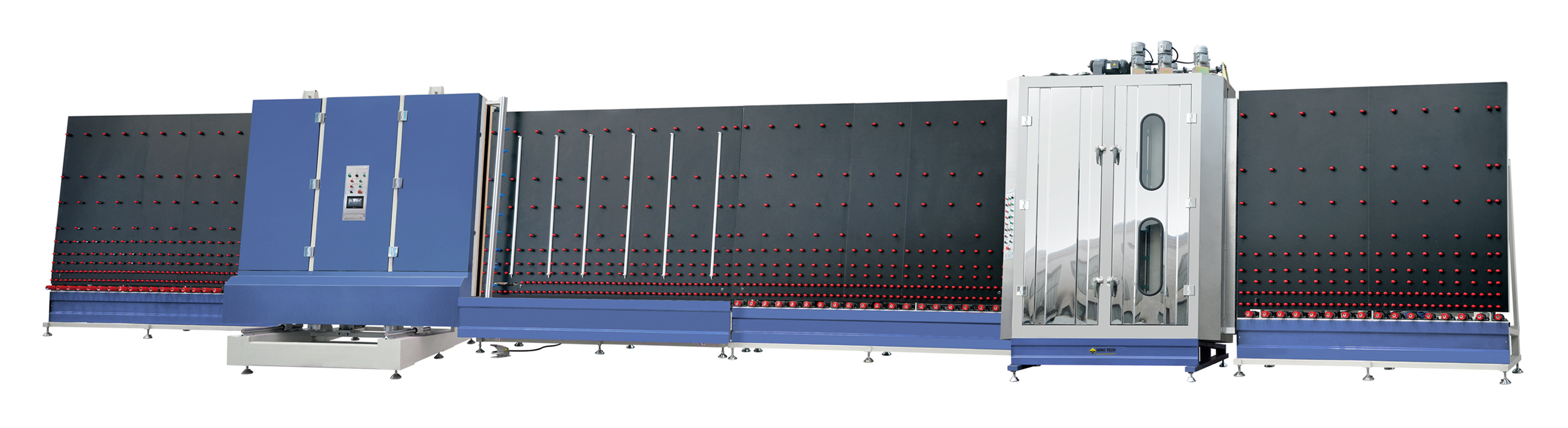

KT-IGL2500 Full Automatic Insulating Glass Production Line(without sealing robot)

Section of Pressing Machine Features:

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position +mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine Features

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are four Six temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Technical Parameters:

Model | GPL-XY2500Y |

Input Voltage | 220/380/480 V 50/60 Hz |

Total Power | 28.5 KW |

Max Glass Size | 2500x3000 mm |

Min Glass Size | 300×450 mm |

Glass Thickness | 4-18 mm |

Working Speed | 8-48 m/min |

Total Weight | 5500 kg |

Size of Line(L×W×H) | 18500*2850*3530 mm |

KT-IGL2500/2000-GF Automatic Gas Filling Insulating Glass Production Line(without sealing robot)

Section of Flat Press:

Italy Technical level of Production ,Installation and Mechanical. Auto Gas Filling Function.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

There is mechanical position & adsorption device system from Taiwan to make it pressing on right position avoid displacement.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45 m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic inside the press machine. Press glass-normal insulted glass, triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair.

When insulating glass is pressed, the front and back part of pressing machine will up the glass with lever-type arm and hand system,(mechanical position + mobile sucking system)all this will ensure no malposition.

Section of Washing&Drying Machine:

Welding by stainless steel with high strength structure ; Top ceiling of it made by 12 mm Thickened stainless steel plate, the bottom is made by 5 mm thick stainless steel ,the lateral is made by 2 mm thick stainless steel.

There are Six High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

The Air drying system designed by air circle with naturally aspirated to keep all process more safe and cleaning.(Automatic air system could keep 40 ℃ of the blowing air).

It is Key-Link style of gear transmission to keep working in high accuracy.

Inside part of wash machine, dry machine and the air dryer are both stainless steel production.It is elegant appearance and never rust.

Technical Parameters:

Model | KT-IGL2000-GF | KT-IGL2500-GF |

Input Voltage | 220/380/480 V 50/60 Hz | 220/380/480 V 50/60 Hz |

Total Power | 19.5 KW | 25 KW |

Max Glass Size | 2000×2500 mm | 2000×3500 mm |

Min Glass Size | 300×450 mm | 300×450 mm |

Glass Thickness | 4-18 mm | 4-18 mm |

Working Speed | 8-48 m/min | 8-48 m/min |

Total Weight | 5200 kg | 6000 kg |

Size of Line(L×W×H) | 18000*2660*3030 mm | 19500*2660*3530 mm |